Greener shipping – A must, but how do you get started?

The demand for advice on making ships more sustainable has increased exponentially in recent months. Private and public fleet owners, inland and maritime operators: they all seem to want to shift things up a gear and are proactively looking for cleaner ships to reduce their ecological footprint.

There is a growing urgency. European fleet owners in particular clearly want to be prepared for growing sustainability demands from customers, cargo owners and governments. We notice that the pressure is increasing in every way, just think of the stricter rules that are coming for shipping traffic in environmentally sensitive and protected areas. Public operators are playing an exemplary role in encouraging users of European waterways to ship greener. Due to the energy crisis and the rising prices for traditional energy sources, the price gap with the ordinarily more expensive alternative drive systems is also narrowing.

Update on alternative energy sources

Today, most ships still run on heavy fuel oil or marine gas oil. But in the foreseeable future, fleet owners might have several sustainable alternatives to choose from. The current focus is mainly on biodiesels, batteries and hydrogen, including ‘hydrogen carriers’ such as ammonia and methanol. Each of these alternatives has both potentials and handicaps. But a wider range of options also makes the choice more difficult. All the more so because many obstacles still have to be overcome before greener energy sources can form a fully-fledged alternative for the shipping sector.

Technology and logistics not yet mature

No alternative energy source is currently 100% technologically nor logistically mature. This makes it challenging for fleet owners to begin to focus on a given energy source, and difficult for governments to decide which production and distribution facilities should be developed on a massive scale. Large-scale production is currently not available for any alternative energy source, let alone large-scale distribution. Hydrogen is, for example, already being used as a raw material in the petrochemical industry, but the production volume is only a fraction of what would be needed if ships were to collectively switch to hydrogen. Moreover, they currently have no place to bunker the necessary quantities. Huge 'hydrogen factories' with electrolysers are needed to convert electrical power (electrons) into hydrogen (molecules). Development is currently fully underway in that area too.

What is green?

Not all green solutions are the same. In other words, not all alternative energy sources are equally green. Hydrogen, ammonia and methanol may be more environmentally friendly than diesel in terms of emissions, but if they are produced from petroleum, they continue to contribute to harmful emissions. The really green option here is hydrogen based on renewable energy, like wind, solar or other climate-friendly production techniques.

Storage limitations

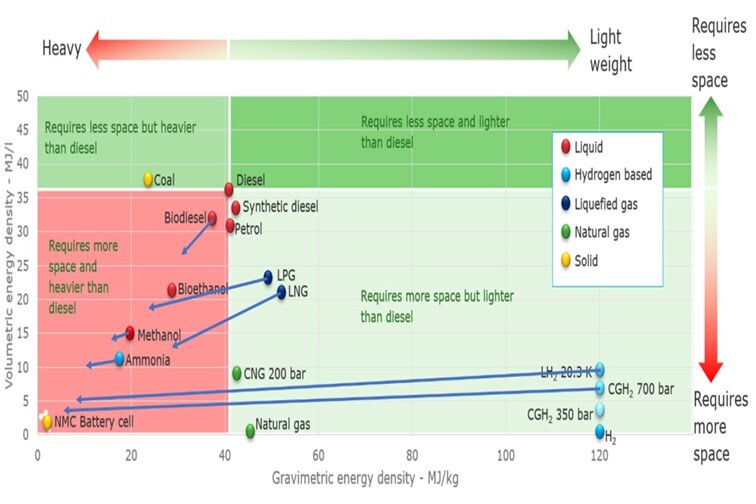

Another factor to take into account when transitioning to an alternative energy source is the low energy density of these carriers compared to diesel. To put it very simply: with a full tank of diesel, you can propel a ship further than with any other energy source. Some are also more toxic (ammonia) or more explosive (hydrogen). This means that the alternative not only takes up more space on board, but also requires additional facilities for safe storage and use. In any case, this means reduced cargo volume on ships. The same goes for that other alternative energy source, batteries, which take up a lot of weight and space and also have to be recharged very regularly. Each of the alternative energy sources will therefore inevitably have an impact on the ships' operations.

Source: "DNV-GL Report No.: 2019-0567, Rev. 3, dated 2019-07-05".

Impact on fuel systems

Fleet owners have to make choices in terms of energy carriers, but also about how the energy on board will be converted into propulsion power. Here, too, there are a number of options. For example, hydrogen can be injected into an internal combustion engine (ICE). However, to initiate the combustion process (unlike diesel, hydrogen does not ignite automatically under pressure), the diesel engine must then either be fitted with spark plugs or, along with the hydrogen, a small amount of diesel needs to be injected that serves as an ignition source (‘pilot fuel’).

As an alternative to ICEs, fuel cells can also be used, which convert hydrogen, ammonia or methanol into electrical energy based on an electrochemical process. This technology is already being used on a smaller scale in cars. The production of larger fuel cells is currently in the development phase. We are monitoring this closely, but it is not yet clear how they can be efficiently integrated into a ship and what risks they will entail.

Is hydrogen the future?

Hydrogen is expected to become the energy source of the future, either in its pure form or stored in ammonia or methanol. In order to increase the storage capacity, research is currently also being conducted into whether hydrogen can be stored in powder form or in porous materials. It must be taken into account that additional steps and components will be required to inject the hydrogen into the carrier and to extract it again later.

We believe that many ships will evolve towards hybrid systems. For example, we see that more and more vessels are being equipped with electric motors and batteries, in combination with another energy source that generates electricity. The combination of diesel and hydrogen systems is also possible.

How to choose the right alternative energy source?

How do you, as owner, determine what will be the most attractive alternative energy source for your fleet? We always advise our customers to start with a very detailed operational shipping profile of their fleet, based on objective measurement data. This will allow to get a good view of all movements of the ships, fuel consumption, power demand, the time that the ship runs at a certain power, etc. Our experience with the clients we guide in this area, shows that the results of such extensive measurements often do not fully match people's gut feeling. In one specific case, for example, it turned out that the ships in question had to run at full power for much less time than was generally believed. Also, the actual measured emissions turned out to be different from what the manufacturers had stated in their spec sheets. In our opinion, an owner can only make the right choices for a greener future for a fleet on the basis of detailed and objective information.

What steps can be taken now?

Operators clearly indicate that they want to make their fleets greener, or at least already want to get to know the options. The difficulty here is that they have to make proactive choices, while there are still many uncertainties and limitations in the field of technology and logistics. With the exception of a few notable pioneers, we tend to see a mostly pragmatic approach when new ships are built. Provisions are made on board to make it relatively easy to switch to a more sustainable energy source in the future.

We always advise our customers not to make hasty decisions. But it's a good idea to start analysing the options in terms of energy sources, energy generators and fuel systems. We offer guidance here, without, however, selling fairy-tale scenarios. The most important thing is that they start with a very detailed operational profile of their fleet, in order to be able to make objective and well-founded choices in the future.

Discover MULTI.engineering's expertise in advising and guiding customers in their transition to a more sustainable fleet

Renewable energy and propulsion systems on board:

- Wind assisted ship propulsion, based on Flettner rotors: 3 commercial projects and 1 R&D project.

- Conversion of harbour tug to methanol: 1 commercial project.

- Conversion of harbour tug to hydrogen (ICE): 1 R&D project.

- Concept of hydrogen bunker barge: pre-commercial project.

- Hybrid propulsion in megayachts: 3 commercial projects.

- Conversion of state operated ships to alternative energy systems: 2 commercial projects.

- Conversion of inland ships to hydrogen energy systems (ICE): 2 pre-commercial projects.

- Ammonia powered fuel cells for ship propulsion: 1 R&D project.

- Hydrogen & methanol propulsion (ICE) for seagoing ships: 1 R&D project.

- Integration of alternative energy systems on board of various ship types, incl. design of zero-emission engine room: 1 R&D project.

Sustainable energy production:

- Tidal turbines at sea: 2 R&D projects.

- Hydrogen production afloat offshore: 2 R&D projects.

- Floating offshore wind energy production: 1 R&D project.

- Floating solar panels: 1 pre-commercial project.

I believe that making well-founded choices for a greener fleet is only possible when you start from a detailed operational shipping profile.