TREASURE plastic catcher project enters new phase

This fall, the bubble curtain technology will be used for the first time to collect plastic waste from a Flemish waterway. This initiative is part of the European TREASURE project, which stands for Targeting the REduction of plAStic oUtflow into the noRth sEa. Project engineer Floris Roelofsen: "We will soon be able to actually measure the effectiveness of the bubble curtain. That will provide us with valuable data for the further roll-out of the plastic catcher."

Where it all started

Six years ago, a UGent student, supervised by MULTI.engineering, launched the innovative concept of using a bubble curtain to collect waste from rivers before it ends up in the sea. "We wanted to develop an installation that's modular and widely deployable," says Floris. "It soon became clear that this would be a challenging ambition because no two locations are the same."

An air barrier for plastic

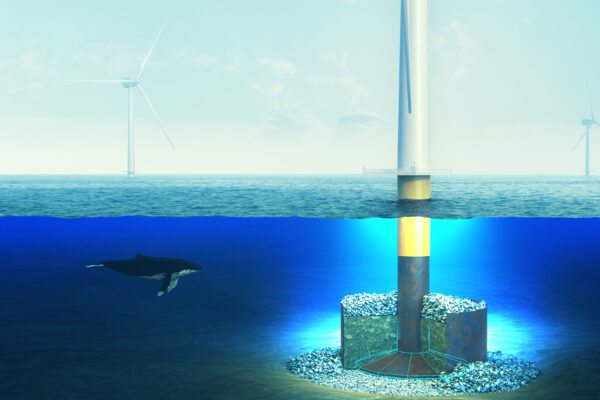

"We create the bubble curtain by forcing pressurised air out of a tube that lies on the bottom of the watercourse," says Floris. "The bubbles hold back the plastic and the current carries it to a catcher."

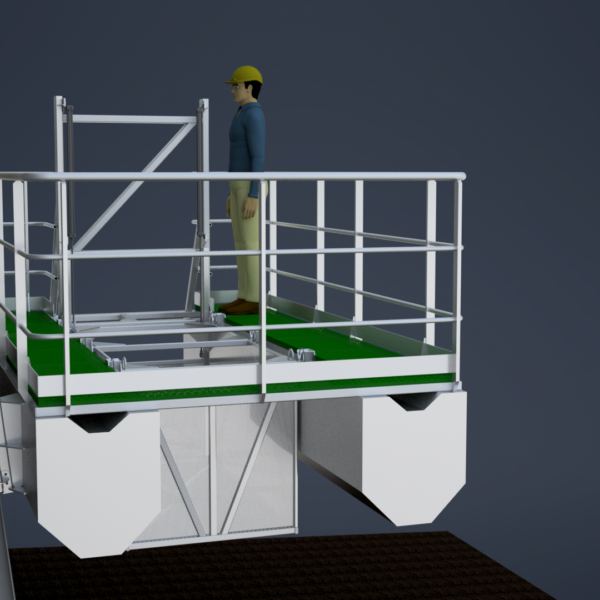

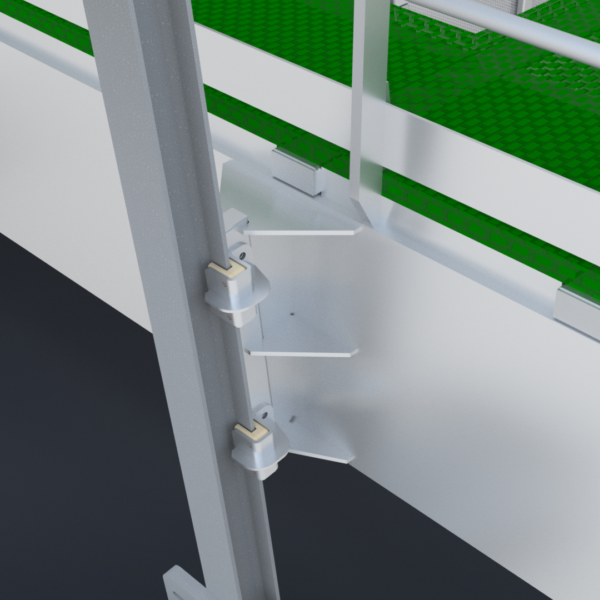

The bubble curtain concept is not new: it's already used for sound insulation during work at sea or to keep fish away from cooling installations. What's unique is that the system works in tides of five metres and does not disrupt the natural flow of the water. "Ships can simply sail through it. And although a compressor is needed for the air bubbles, it also uses natural forces to catch the plastic. As soon as the current reaches a certain force, the air compressor starts automatically. If it decreases, the system stops automatically. So there's hardly any supervision required, only someone who regularly collects the waste from the catcher."

Five living labs under TREASURE

The R&D trajectory with the bubble curtain is subsidised through the TREASURE project, which aims to reduce the amount of plastic waste that ends up in the North Sea. The core of the project consists of five living labs. One of them will start soon in Nieuwpoort. "Living lab Nieuwpoort will put the bubble curtain into practice from September onwards. With the data that the pilot project provides, we then want to optimise and commercialise the concept."

The TREASURE project is being carried out in the Ganzepoot in Nieuwpoort. This is a water system where six waterways come together that connect the IJzer and the North Sea.

The driving forces in the TREASURE project

MULTI.engineering plays a crucial role in the design and implementation of the TREASURE project. "Together with IMDC (International Marine and Dredging Consultants) we investigated the current and determined a suitable location to collect plastic. IMDC is an international engineering firm specialised in natural waters. The size of the system and the capacity of the compressor were adjusted to all environmental factors. In addition, we entered into discussions with the municipality and other stakeholders to obtain approval for our plans. That was the biggest challenge in this project for me, because it's a step that is not necessary in our commercial projects. In any case, it gives a new dimension to the process."

Other partners also actively contribute to the development and implementation of the system. IMDC performs simulations to understand how the waste behaves and how the flow in Nieuwpoort works. VLIZ Oostende supervises the living lab and is involved in stakeholder engagement. The Municipality of Nieuwpoort and the Province of West Flanders ensure the necessary approvals. Finally, Herbosch-Kiere is responsible for the practical implementation of the system.

TREASURE on the commercial market

The goal is to ultimately bring the plastic catcher onto the market. "That will be easier if we can demonstrate in practice how effectively the bubble curtain works," says Floris. "We have a lot of expertise in-house and have already gained important insights from simulations. Now it's time to test these insights against reality."

"In any case, it's important to properly map out criteria such as water depth and flow in order to validate the size of the system and the capacity of the compressor. The deeper you go, the more air pressure you need. Based on these calculations, we can determine where the bubble curtain will be most efficient and therefore most profitable. The plastic catcher certainly offers many possibilities. It's a promising solution for removing plastic from our waterways."

The bubble curtain plastic catcher offers a promising solution for removing plastic from waterways. The test phase that will start soon will help us determine where this technology can be used most efficiently