Sea-fastening and deck integration analysis for wind turbine blade and nacelle transportation

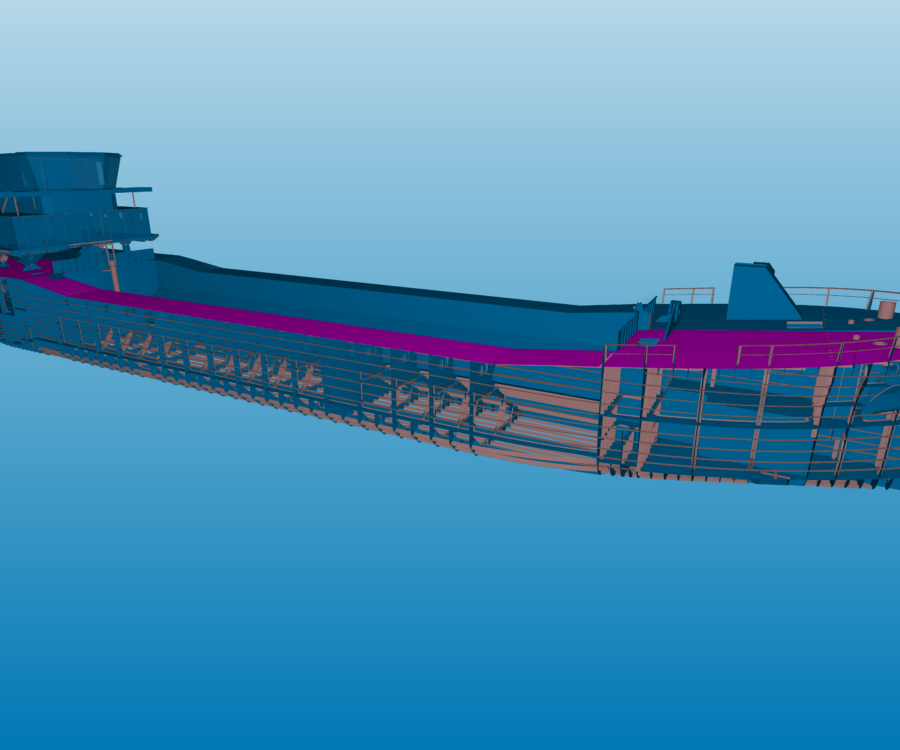

Jan De Nul8 wind turbine blades and 4 nacelles needed to be shipped for off shore installation on different locations. Together with other wind turbine parts, the blades and nacelles were placed on the main deck of an off shore installation vessel.

SPECIFICATIONS AND CHALLENGES

MULTI.engineering was invited to perform a strength assessment of the sea-fastening of the wind turbine blades and nacelles. The blades were positioned on the several levels stack and put on the grillage with the relevant stoppers. The nacelles were stored on board by using stoppers that are welded to the main deck.

RESULT

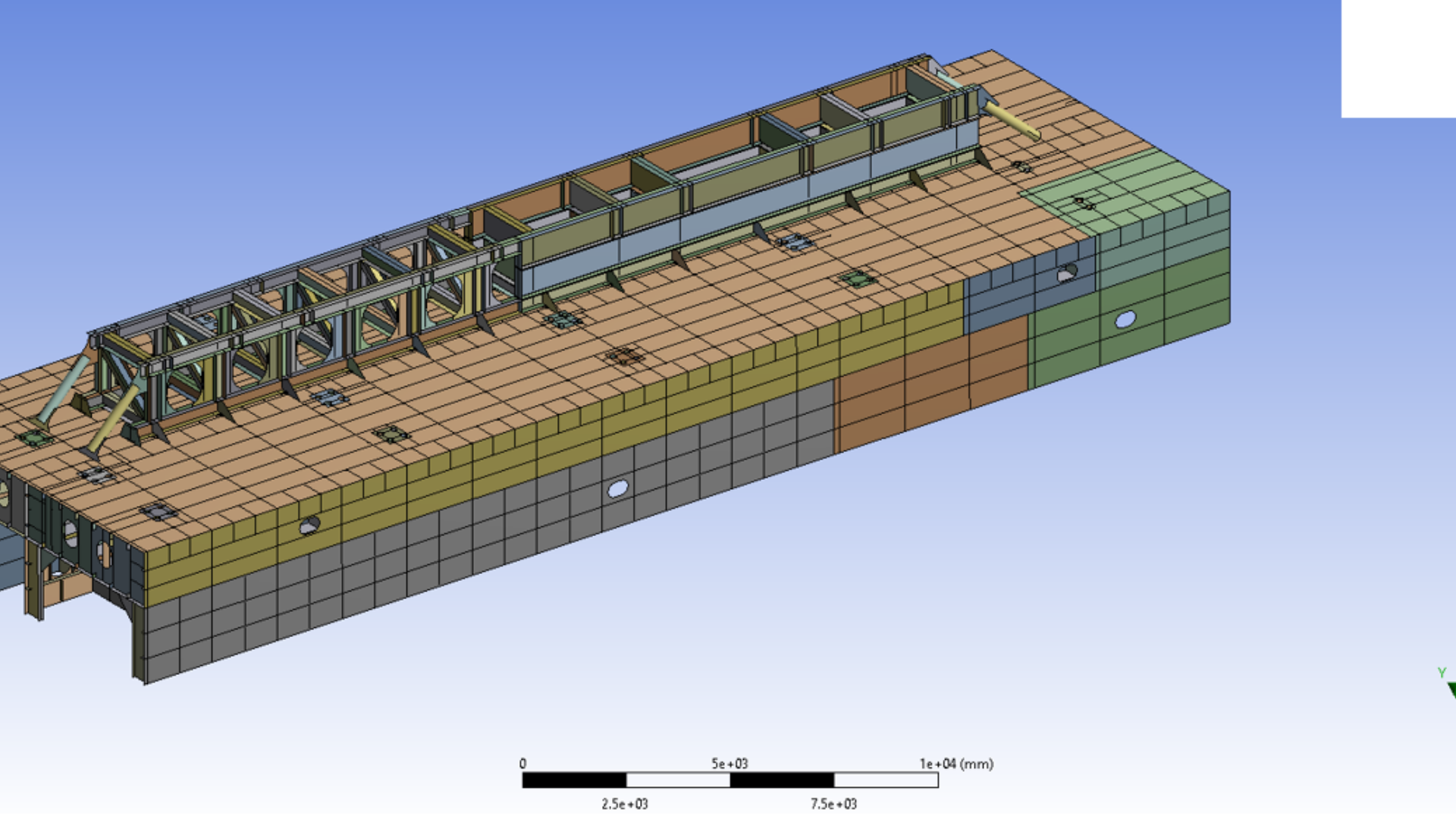

Stoppers, surrounding main deck structure and welds were checked by “hand calculations” for shear-, bending- and buckling strength at the first design stage. As a second step, the entire nacelle frame and surrounding main deck structure were assessed and optimized by means of Finite Element Analysis.

ADDED-VALUE MULTI.ENGINEERING

With the experience and flexibility of MULTI.engineering, Jan De Nul was able to finalize this challenging task within the required timeframe and with high efficiency in terms of structural optimization.

CLIENT

Jan De Nul, contractor active in dredging, land reclamation, pipe laying, salvage and installation projects.

• Approx. 6,875 employees.

• Active in 38 countries.

• Family owned.

SCOPE

Hand calculations and FEA strength assessment of the stoppers and surrounding main deck structure of the wind turbine blades and nacelles sea-fastening.

SERVICES PROVIDED

• Manual strength assessment

• FEM calculations