Conversion enhances sustainability of DEME Group’s Orion

This spring, DEME successfully completed the conversion of its vessel, the Orion. Now operational, the ship is demonstrating remarkable proficiency in the swift and effective installation of bottom-fixed foundations for offshore wind farms within US waters. In this interview, Luca Zanette who was Project Manager for the conversion, provides insights into why and how this conversion was carried out.

Upgrading exhaust system and cleaning processes

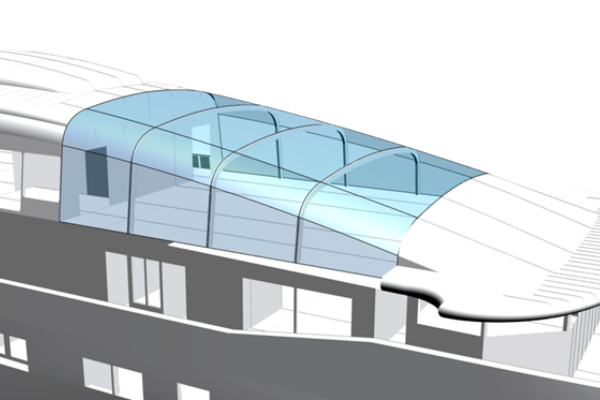

The Orion is a heavy lifting installation vessel designed for the offshore wind industry. It represents a departure from the conventional jack-up design of similar vessels. Instead, it introduces a monohull floating platform concept with a robust onboard crane that makes it exceptionally efficient in installing bottom-fixed foundations for wind farms, and also other applications in the future.

However, for operation within US waters, the vessel had to undergo a conversion due to the stricter emission regulations in place there. The refit of the Orion involved the integration of NOx exhaust cleaning equipment to achieve IMO TIER III Certification .

Seamless project management

“A crucial part of the replacement of old sections of the exhaust installation with new components, our task involved cutting into specific structures and installing new piping, cables and secondary frameworks. In this intricate process, MULTI.engineering played a pivotal role in engineering the way the installation was handled, in collaboration with DEME design team.”

During the conversion process, DEME and MULTI.engineering faced the common challenges associated with a refit. “In this case, this challenge was exacerbated by the rarity of refits involving this type of equipment. Its standard version clearly wasn't designed with the idea of fitting it into the existing structures of a functioning vessel.

MULTI.engineering conducted an on-board 3D scan of the areas designated for the new equipment installation and subsequently compared the scan results with the shipyard's original construction information. By consolidating these two datasets, they formulated the design for the interfaces and the comprehensive integration plan.”

Meeting rigorous emission standards

From a project management perspective, the conversion was a success, Luca says. “We adhered precisely to the schedule, stayed within the budget, and the new exhaust system is functioning effectively. Rigorous testing protocols have demonstrated that NOx emissions remain below the specified thresholds. As a result, both the vessel and all its engines have been granted IMO Tier III certification, confirming their full compliance in both gas and diesel modes. Good teamwork among internal and external stakeholders made this possible”

Pioneering a greener maritime future

According to Luca, refits similar to the one conducted on the Orion are expected to become more frequent due to increasingly stringent regulations overall, combined with the rapidly growing importance of the offshore wind markets outside Europe, such as US.

The Orion's conversion is not an isolated case but rather a part of a comprehensive sustainability programme aimed at aligning with the International Maritime Organization (IMO)'s sustainability policies and meeting European climate objectives.. To achieve these goals, we are implementing several initiatives, including enhancing the efficiency of onboard systems on existing ships and installing waste heat recovery and emission cleaning systems. Both of the most recent additions to our fleet, namely Orion's sister ship, the Green Jade, and the Viking Neptun, have already been equipped with the SCR system (Selective Catalytic Reduction). And, of course, we are – together with other parties in the shipping industry – actively investigating the potentials of (low and net zero carbon) fuels. DEME Group’s goal is a 40% GHG intensity reduction by 2030 (rel to 2008) and climate neutral operations by 2050.

Ship conversions are inherently complex endeavours. Yet, with the Orion, the challenge was compounded by the rarity of retrofits involving this specific type of equipment.